| Part Number: CAMSS-HIT-20Q32-Medical-T (Tan) | Part Number: CAMSS-HIT-20Q32-Medical-G (Green) |

| General Info |

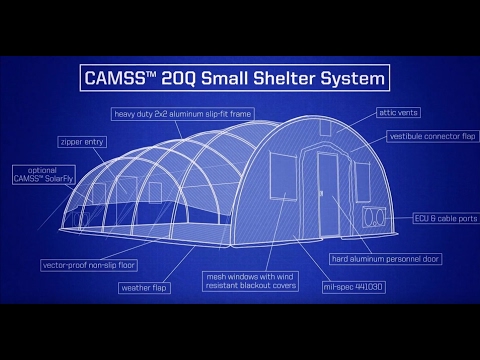

- Measures 20’ wide x 32’6” long x 10’ tall

- Usable area of 650 square feet

- 1150 lbs unpackaged

- Assembles in 30 minutes with trained four-person crew

- Used for medical clinics, hospitals

|

| Cover / Ends |

- 15 oz/sq yd Mil-Spec 44103D fabric

- Vestibule connectors over entries can be used to connect to other shelters or vestibules

- Includes two (2) sets of two (2) 18” ECU ports with a cable port

- Total of four (4) mesh windows with wind resistant blackout covers

- Twelve (12) guy ropes for high wind

- Can connect multiple shelters end to end with integrated connector flap

- Built in infrared blocking

- Fabric includes UV inhibitors and is mold and rot resistant.

- Fire resistant fabric that meets NFPA 701

- Cover and ends are radio frequency welded

- Each end panel includes mesh attic vent with cover

|

| Personnel Entries |

- Two (2) double zipper entry (48” W x 84” H)

- Tie offs to hold door open

- Wider doorways to allow easy access for gurneys

- Centered on ends of the shelter

|

| Frame |

- Made from lightweight, high-strength aluminum

- Arches are made with 2”x 2” aluminum square tube

- Continuous base frame to provide vector proofing

- Frame components are interchangeable and color coded to speed assembly

- Pre-drilled base frame for easy anchoring

- Base frame includes connection points to secure cover to frame

- Frame is corrosion resistant aluminum

|

| Fabric Floor |

- 15 oz/sq yd non-slip Mil-Spec 44103D

- Floor system is secured to the base frame

- Removable for cleaning and replacement without disassembly of shelter

- Continuous hook and loop perimeter for vector proofing to keep bugs and critters out

|

| Liner |

- Shelter includes an internal liner system that helps to maintain internal working conditions of 40° – 80° F in ambient temperatures of -25° to 125° F when supported by a 5-Ton military environmental control unit

- Air sock runs the length of the shelter and has spot cooling

- Single piece liner system allows for easy installation

- 8 oz/sq yd Mil-Spec fabric

- Liner is flame resistance per test method ASTM D6413

- After flame – 2 seconds max

- Char length – 6” max

|

| Electrical |

- Single phase electrical panel

- Two (2) GFCI 20A breakers

- Two (2) 20A breakers

- One (1) light switch with breaker

- Four (4) twist lock cable connectors

- Two (2) outlet lines with a total of twenty-four (24) quick connect 110V outlets

- Ten (10) quick connect incandescent lights with protective metal cages

- 50 ft. 20A power cable included

|

| Anchoring |

- Thirty-six (36) double headed 18” base frame spikes

- Twelve (12) guy ropes and guy spikes

|

| Spares / Repair |

- 30 day spares/repair

- Patch materials for cover, liner, and floor which are all air transportable without special hazmat requirement

|

| Tools & Equipment |

- Verified manual

- Sledge hammer

- Spike puller

- Four (4) pull over ropes

|

| Life Expectancy / Warranty |

- Shelter has a usable life of 10 years and a 20 year storage life

- Shelter includes a standard manufacturer’s warranty

|

| Packaging |

- Wood crate

- Forklift ready and Export approved

- 43” W x 101” L x 30” H

- 310 lbs (empty crate)

- 1460 lbs (total weight with shelter)

- Six fit on a 463L pallet

|

| Testing & Engineering |

- Maintain internal temperatures of 40°F to 80°F in ambient temperature of -25°F to 125°F when supported by a 5-ton military environmental control unit

- Meets Test Operations Procedure (TOP) 10-2-175 Tents and Shelters wind load test

- Engineering calculation demonstrate shelter performance will meet a 100 mph wind load per ASCE 7-16

- Meets Test Operations Procedure (TOP) 10-2-175 Tents and Shelters snow load test

- Engineering calculations demonstrate shelter performance will meet a 20 psf ground snow load per ASCE 7-16

- Meets Test Operations Procedure (TOP) 10-2-175 Tents and Shelters blowing rain test

- Meets Test Operations Procedure (TOP) 10-2-175 Tents and Shelters blackout test at a minimum distance of 100 meters with the naked eye

- Meets Test Operations Procedure (TOP) 10-2-175 Tents and Shelters blackout test at a minimum distance of 300 meters with night vision goggles

- Meets 20 Set-up/Strikes cycles of durability testing per U.S. government test

|

| *Design loads assume that actual soil conditions will meet one of the following in accordance with ASTM D-2487/2488:

- Sand gravel / very dense sand

- Hardpan / Asphalt

*Fabric weights are nominal

*Dimensions are nominal

|